Interim CIO: Dr. Claus Michael Sattler

When data develops drugs

An in-depth case study on digital transformation in the pharmaceutical industry

The pharmaceutical industry is facing one of its biggest challenges in decades. While the world waits for innovative medicines, pharmaceutical companies are struggling with increasing regulatory requirements, growing costs and ever more complex production. In this context, data is becoming a decisive success factor – it enables processes to be optimized, quality to be assured and innovations to be brought to market faster.

Introduction

Why data is revolutionizing medicine

Today, data is the new gold – especially in the pharmaceutical and healthcare sectors.

While the development of a new drug used to depend primarily on laboratory results, clinical studies and the expertise of researchers, digital data now plays a central role. It helps to understand production processes, avoid errors and develop new active ingredients more efficiently. However, the path from data collection to data-driven production is full of obstacles – as the following case study shows.

The initial problem: Data chaos in a traditional pharmaceutical company

A good ten years ago, I joined a pharmaceutical company specializing in the development and production of chemotherapeutics and HIV drugs as an interim CDO. The company had 40 years of experience – an immense wealth of knowledge that was hidden in paper files, unstructured files and isolated systems.

Paper-based and unstructured data

Most of the information was available on paper. Even though digital systems were already being used in many areas, there was a lack of standardized, structured data management. Employees recorded data in tables and text documents, which they adapted as required – often without regard to GMP (Good Manufacturing Practice) rules or other regulatory requirements.

The result: an almost unmanageable variety of formats and structures that made it impossible to use the data centrally.

Data logger without interfaces

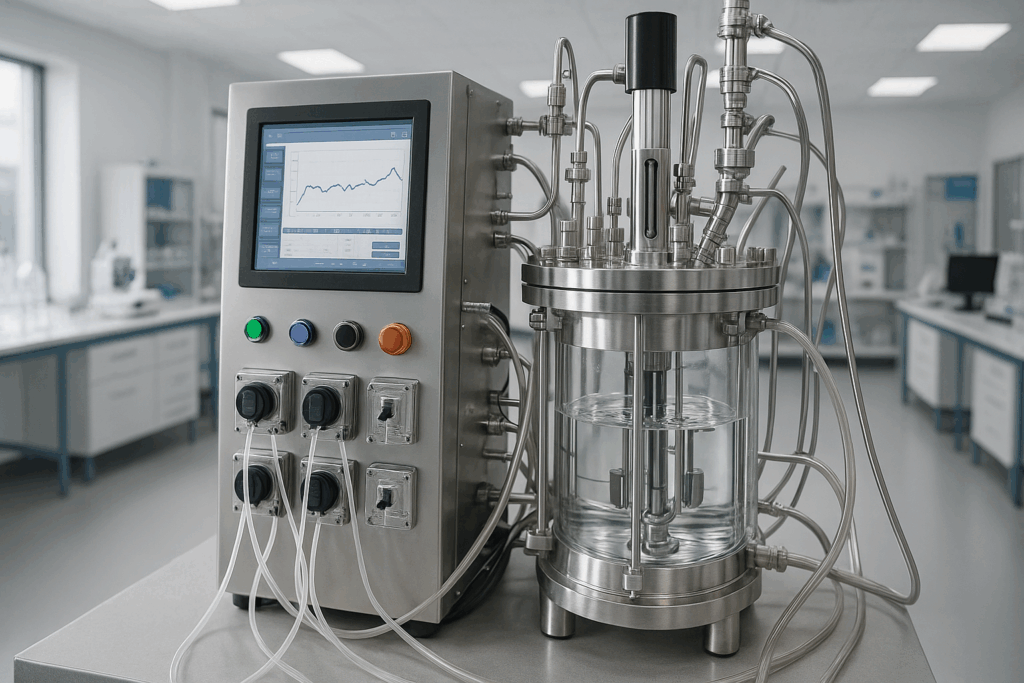

Numerous sensors and data loggers were used in production to record measured values such as temperature, pressure, pH value and other parameters. However, this data could not be exported digitally. The manufacturer of the data loggers referred to regulatory requirements of the European Medical Agency (EMA) and the US Food and Drug Administration (FDA) and refused to provide an interface.

As a result, the valuable production data remained trapped in the devices and could not be used for analysis.

Massive flood of data without structure

Over the years, the company had accumulated an almost unmanageable amount of data records: 1.6 million Excel, Word and PDF files with a wide variety of structures and formats. Every employee, every project, every department had developed its own procedures for data collection and storage.

As a result, it was practically impossible to use this data centrally.

Head monopolies and isolated networks

Knowledge was highly fragmented within the company. Many employees had “head monopolies” – their knowledge was not documented and / or only accessible to them. The IT infrastructure was divided into hermetically separated networks for production, facility management, research and development and administration.

As a result, it was virtually impossible to exchange data between the divisions.

Lack of central data storage and real-time analysis tools

The company did not have a central platform for storing, managing and analyzing data. There was a lack of software that could systematically process unstructured data and make it usable.

As a result, real-time analysis of production data from the bioreactors was not possible.

The solution: from data collection to data-driven production

Radical changes were necessary to turn the data chaos into a resource. The solution approaches can be summarized in three central measures.

The data bridge: secure connection of silos

The first challenge was to connect the separate data worlds – without violating the regulatory requirements. The solution was a highly secure “one-way street”: a data bridge that transferred data from production, research, facility management and administration to a central administration. This bridge was designed to guarantee the integrity and security of the data while meeting regulatory requirements.

Technical implementation:

The data bridge was based on a specially developed protocol that only permitted one direction: from the production networks to the administration. Return channels were excluded to prevent manipulation. The data was encrypted before transfer and checked for integrity after transmission. This ensured that no unwanted changes were made and that the regulatory requirements were met.

The object-oriented database: Integration and conversion

In the next step, all data – regardless of format and structure – was transferred to an object-oriented database. This database was able to take over different data structures, convert them and make them available for analysis.

Advantages of the object-oriented database:

- Flexibility: The database was able to map and adapt different data models without losing the historical data.

- Scalability: Even large volumes of data could be processed and analyzed efficiently.

- Interoperability: The database enables the exchange of data with other systems, for example for reporting or regulatory purposes.

Data conversion:

Converting the unstructured data was one of the biggest challenges. Special tools were used here that automatically analyzed and structured texts, tables and PDFs and transferred them to the database. Metadata such as creation date, author and context were also saved to ensure traceability.

Real-time data analysis: process optimization in real time

With the integration of all data, it was possible to set up a real-time data analysis. This analysis platform continuously monitored all production steps – from cultivation in the bioreactors to purification (upscale, downscale, filtration, inactivation, polishing) and the final extraction of the drug substance.

Technical details:

- Data visualization: The platform offered intuitive dashboards that displayed the current status of all production processes in real time.

- Alarm functions: Alarms were triggered automatically in the event of deviations from the target values, so that immediate action could be taken.

- Historical analyses: The platform made it possible to compare current and historical data in order to identify trends and patterns.

Insights: Data as the key to process optimization

The systematic use of the data led to surprising findings that changed the company in the long term.

Seasonal production deviations

The analysis showed that the quality and quantity of the active ingredients produced are subject to seasonal fluctuations. These fluctuations had previously gone unnoticed as they were hidden in the unstructured data. Through continuous monitoring, these patterns could be identified and specifically addressed.

Permanent overview of all production processes

The real-time analysis enabled a permanently up-to-date overview of all production processes in all bioreactors and the downstream stages. This meant that problems could be identified and rectified at an early stage before they led to quality problems or production downtime.

Influence of weather and ambient conditions

The data analysis revealed that external factors such as temperature and weather can have a significant impact on production. This insight was the starting point for the development of forecasting algorithms that significantly changed production planning and control.

Results: From forecasting to cost reduction

The consistent use of data had a measurable impact on production and company performance.

Development of forecasting algorithms

Algorithms were developed that could predict the influence of weather and environmental conditions on production. These algorithms used historical and current data to forecast the expected quality and quantity of the drug substance in real time – without delay.

Example:

An algorithm analyzed the production data from the last five years and correlated it with weather data. This showed that certain weather conditions (e.g. high humidity in summer) led to increased variability in production. The algorithm was able to recognize these correlations and incorporate them into the forecast.

Reduction of deviations

The early detection of influencing factors that could lead to deviations and the targeted control of production processes have significantly reduced fluctuations in quality and quantity. Production became more stable and predictable.

Cost reduction

The optimization of processes and the reduction of deviations led to a significant reduction in production costs. Resources were used more efficiently and rejects and “rework” were reduced.

Transparency and compliance

Central data storage and real-time analysis improved transparency and compliance with regulatory requirements. Every production step was traceable and documented, which made compliance with GMP, EMA and FDA requirements much easier.

Outlook: The digital transformation in the pharmaceutical industry

The experience gained from this project shows how important data management and digital technologies are for the pharmaceutical industry. Digital transformation is not an end in itself, but a necessity in order to remain competitive and develop innovative medicines efficiently.

Key technologies and trends

Artificial intelligence (AI) and machine learning:

AI enables the analysis of large amounts of data, the identification of patterns and the prediction of production results. This allows processes to be optimized, errors to be detected at an early stage and resources to be used efficiently.

Internet of Things (IoT):

Sensors in bioreactors and production facilities continuously provide data that can be used to monitor and control processes. IoT-supported solutions improve quality assurance and production efficiency.

Blockchain:

Blockchain technology ensures transparency and security in the supply chain. Every step – from production to delivery – can be traced, which prevents counterfeiting and quality problems.

Cloud computing and big data:

Cloud-based platforms enable the central storage, processing and analysis of data. Big data analyses provide valuable insights for research, development and production.

Challenges and recommendations for action

Data integration:

The biggest challenge is to integrate data from different sources and formats and make it usable. Central data storage and standardized interfaces are crucial.

Regulatory requirements:

Compliance with GMP, EMA and FDA regulations is essential. Digital solutions must be designed to meet regulatory requirements and guarantee the integrity of the data.

Cultural change:

The digital transformation requires a cultural change within the company. Employees must be prepared to use new technologies and share knowledge. Head monopolies and isolated working methods must be overcome.

Shortage of skilled workers:

The introduction of digital technologies requires qualified employees. Companies need to invest in further training and new job profiles.

Practical example: A day in data-driven production

To illustrate the advantages of data-driven production, here is an example of a daily routine:

Early in the morning:

Production management starts the day with a look at the central dashboard. There they can see the current status of all bioreactors, the running processes and any deviations. An alarm indicates that the temperature in a bioreactor is slightly above the target value. The team intervenes immediately and adjusts the settings.

During the day:

The real-time analysis continuously monitors all production steps. The algorithms predict that the yield in a particular process step could drop slightly due to the current weather conditions. Production planning is adjusted accordingly.

In the evening:

The daily data is automatically transferred to the central database and compared with historical data. The evaluation shows that production has been stable and efficient. The compliance documentation is complete and available for audits.

The future: data as a driver of innovation

The digital transformation in the pharmaceutical industry is not a short-term trend, but a fundamental change that affects all areas of the company. Data is the key to optimizing processes, reducing costs and developing innovative medicines. Companies that use their data systematically and invest in digital technologies will remain competitive in the long term and help shape the future of medicine.

Technical standards and regulatory requirements

GMP, EMA and FDA: What does this mean for data integration?

The pharmaceutical industry is subject to strict regulatory requirements. Good Manufacturing Practice (GMP) stipulates how production processes must be documented and monitored. The European Medical Agency (EMA) and the US Food and Drug Administration (FDA) also require all data to be stored in a tamper-proof and traceable manner.

Challenges in data integration:

- Audit trail: Every change to a data record must be logged.

- Data integrity: Data must be protected against unauthorized changes.

- Traceability: Every production step must be documented and reconstructable.

Solution approaches:

- Encryption and digital signatures: Data is transmitted in encrypted form and provided with digital signatures to ensure its integrity.

- Central data storage: A central database with strict access rights and logging of all changes.

- Automated backups: Regular, automated backups protect the data against loss or manipulation.

Technical standards for data integration

Interfaces and protocols:

- REST APIs: For the exchange of data between different systems.

- MQTT and OPC UA: For communication with sensors and control systems in production.

- ETL processes (Extract, Transform, Load): For transferring data from different sources to the central database.

Data modeling:

- Object-oriented databases: Enable the flexible mapping of complex data structures.

- Semantic data models: Facilitate the integration and interpretation of data from different sources.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Change management: taking employees with you

The digital transformation is not only a technical challenge, but also an organizational and cultural one. Employees need to be won over to the new technologies and processes.

Measures:

- Training courses and workshops: Regular training courses teach employees the benefits and how to use the new systems.

- Transparency and communication: Open communication about goals, progress and challenges creates acceptance.

- Participation: Employees are actively involved in the design of the new processes.

Future prospects: What comes after digitization?

Digitalization is just the beginning. In the future, other technologies will change the pharmaceutical industry:

- Artificial intelligence in drug development: AI helps to identify and test new active ingredients more quickly.

- Personalized Medicine: Data makes it possible to tailor medication to the individual patient.

- Predictive maintenance: sensors and data analysis help to predict and prevent machine failures.

Conclusion: Data as a driver of innovation

The digital transformation in the pharmaceutical industry is not a short-term trend, but a fundamental change that affects all areas of the company. Data is the key to optimizing processes, reducing costs and developing innovative medicines. Companies that use their data systematically and invest in digital technologies will remain competitive in the long term and help shape the future of medicine31620.

The case study impressively demonstrates how data chaos can be turned into data-driven production. The integration, analysis and use of data makes it possible to optimize production processes, ensure quality and reduce costs. Digital transformation is not an end in itself, but a necessity for the pharmaceutical industry – today and in the future.

Personal results

As an interim manager, responsible for digitalization and digital transformation in this pharmaceutical company, I was able to significantly advance the digital transformation of the company. I have shared my experience in the following publications and presentations:

- Co-author of the book “Digital Transformation of Services in Healthcare VII: Impulses for the Pharmaceutical Industry”: From Data to Vial: The Impact of Vertical IT Integration on the Success of CDMOs”, I show how important the integration of company data is for the biopharma industry and derive recommendations for action.

- Co-author of the book “Künstliche Intelligenz im Gesundheitswesen: Developments, Examples and Perspectives”: In my chapter “Simply think differently about data! Big data (BD) and artificial intelligence (AI) in practice”, I shed light on the importance of data for pharmaceutical production and offer creative approaches for implementation in companies.

- Keynotes at international congresses and university lecturer: I have passed on my experience at numerous international congresses and in lectures at Bremen University of Applied Sciences, IMD in Lausanne and WHU – Otto Beisheim School of Management and look forward to further platforms.

The discussion on LinkedIn

You can follow the discussion on LinkedIn at https://www.linkedin.com/posts/claus-michael-sattler_ohne-daten-f%C3%BChren-hei%C3% 9Ft-blind-flying-activity-7336266779419140098-c5V_.